See also: DIY Campervan Mini Projects >>>

DIY Fit-out | What size van? | Draw a floor plan | Cabinet materials | Fittings | 12V power

Campervan cabinet construction

Normal carpentry practices and materials that might be appropriate in a domestic residential environment don’t necessarily apply when fitting out a motor vehicle which will be travelling on public roads at speeds of 100 km/h, climbing and descending steep hills, bouncing over potholes and corrugations, or pushing around unexpected tight corners!

Normal carpentry practices and materials that might be appropriate in a domestic residential environment don’t necessarily apply when fitting out a motor vehicle which will be travelling on public roads at speeds of 100 km/h, climbing and descending steep hills, bouncing over potholes and corrugations, or pushing around unexpected tight corners!

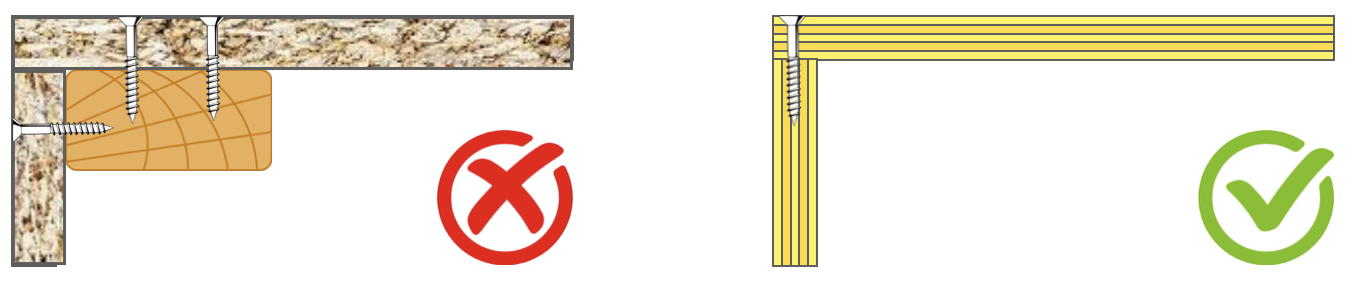

I do worry when I see DIY Campervans being fitted out with regular pine frames clad with solid timber or domestic-style composite board materials. Or kitchen areas with solid timber (or engineered stone) bench tops and walls lined with grouted tiles. This stuff weighs a ton. Literally. (Refer to your vehicle’s legal GVM.)

Solid timber, particularly widely available cheap pine (with lots of knots), may not be dimensionally stable over time in the extreme temperature environments encountered in a Campervan.

Be wary of vans that have been fitted out with pine lining boards, glossy white cupboards and other cozy domestic materials. These vans appear to be designed more to meet the needs of the Vanlife, Pinterest and Instagram photo shoots, rather than the practical (and legal) requirements of life on the road.

The ideal material to use when fitting out a Campervan is good quality plywood. It has an excellent strength-to-weight ratio.

Definitely don’t use composite particle board products, often available at hardware supply stores with a melamine laminate finish. This material is relatively heavy and will not be durable in a vibration-prone mobile environment.

Good quality plywood can facilitate a stable frameless construction. (Keep in mind that Campervan cabinets are secured to the van body, so don’t need to be completely free-standing.) Pre-drill screw holes in ply to avoid splitting, and apply a dab of silicone to the hole before inserting the screw – this will prevent the screw working loose over time….

Gross Vehicle Mass (GVM)

When your van is fully loaded and ready to go, drive to a weigh bridge (the local council recycling centre is usually a convenient location) and check that it does not exceed the GVM listed in the manufacturer’s specifications. Being too heavy is not only dangerous, but will likely void your insurance if you are involved in an accident. Keep this in mind as you enthusiastically build cabinets and install appliances in your van. If necessary, it may be possible to install a suspension upgrade to increase your van’s legal GVM. |

Plywood options

Plywood is manufactured with laminated layers of ‘peeled’ timber veneers, the grain of each layer glued perpendicular to the adjoining layers.

Plywood is manufactured with laminated layers of ‘peeled’ timber veneers, the grain of each layer glued perpendicular to the adjoining layers.

It is structurally very strong. Correctly designed, cabinets constructed from plywood (and anchored to the vehicle) are robust and long-lasting, and don’t require an over-engineered frame.

For most Campervan requirements, good quality 12mm ply is the ideal material.

There are two major categories of plywood – structural and non-structural. In the non-structural category (in which we are interested) there are further classifications – marine, external, and internal grades…

-

- Structural – used on construction sites for building frames, etc;

- Non-structural – used in cabinet construction, wall linings, etc;

- Marine – used where there may be direct contact with water;

- External – used where there will be exposure to the weather;

- Internal – used for cabinet work, wall linings, etc.

Marine grade is the most durable, and most expensive plywood, but only required where the plywood will be in direct contact with water. Marine grade plywood incorporates higher quality water-tolerant timbers such as hoop pine, and the layers of veneers are laminated with phenol formaldehyde glue. Marine ply will survive direct contact with water – not really necessary when considering the needs of the average Campervan.

Exterior grade plywood uses melamine urea formaldehyde glue, which will be more tolerant of long term weather exposure. Again, not really necessary in the average Campervan environment.

Internal grade plywood is generally fine for a Campervan fitout. Most modern non-marine plywood products are now laminated with a urea formaldehyde glue, which is also waterproof and stable over time. There may still be some cheap plywood available that uses PVA glue – you don’t want this, as it will degrade over time. Check with your supplier.

Plywood is classified in grades (A to D), which is indicative of the quality of the timber veneers used in the plywood manufacture.

Two alphabetical letters are often used to describe plywood grade – one to designate the grade of the ‘face’ layer and the other the grade of the ‘non-face’ layer of the ply. Our local supplier recommended ‘BC grade’ as plywood suitable for Campervan cabinets – good quality at a reasonable cost.

You can choose between ‘laminated’ ply, with a decorative and durable plastic laminate surface finish applied, or ‘natural’ ply with a plain timber finish. Other than the finish, the big difference is cost – plywood with a plastic laminate finish applied is around $250 a sheet while non-laminated-finish ply of the same quality is around $70 a sheet. And it is not too difficult to apply the plastic laminate to the cheaper material yourself if budget is an issue.

Given the durability issues likely to be experienced in a Campervan environment, I would be going for a ply with a durable plastic laminate finish.

When discussing options with a plywood stockist, also take into consideration the varying temperatures that you are likely to encounter in a Campervan environment – often getting very hot, which may impact on the glue bond of cheap plywood in extreme conditions.

Lightweight marine ply for Campervans?

I took a piece of ‘lightweight marine ply’ from a friend’s factory-built Campervan to our local plywood supplier as an example when looking for a similar product. The ply had a decorative plastic laminate finish and, to me, it certainly felt very light! The plywood supplier chuckled when presented with my sample, and proceeded to cut a piece of ‘regular’ ply to exactly the same size as my ‘lightweight’ example. He then took both pieces to the scales in his office. Guess what? They both weighed the same. In fact the ‘regular’ sample was a little lighter than the ‘lightweight marine ply’ sample, probably due to the weight of the plastic laminate finish on my sample piece. And as for the ‘marine’ aspect – according to the supplier, these days all reasonable quality ply is laminated with urea formaldehyde glue (not PVA), which for all intents and purposes is as waterproof as you would need in a Campervan. I suspect that the term ‘lightweight marine ply’ may just be an industry marketing phrase, a hangover from a bygone era when cheap PVA-bonded plywood was more prevalent. |

Huh?

All a bit confusing?

If you are considering a DIY van fit-out, head down to your local specialist plywood supplier and chat to them about your needs. They will be able to recommend a product, and may even be able to cut it to your sizes, and apply a finishing material to the edges.

If you are considering a DIY van fit-out, head down to your local specialist plywood supplier and chat to them about your needs. They will be able to recommend a product, and may even be able to cut it to your sizes, and apply a finishing material to the edges.

The link below provides some examples of various plywood products, including lightweight plywoods suggested for use in caravans and transportable buildings – but only for wall and ceiling linings. (I haven’t used these ‘lightweight’ materials – I expect they may not be suitable for cabinet construction.):

-

- Gen-Eco Plywood >>> (Check options at top of screen)

In a nutshell, the most important aspect of cabinet construction in a Campervan environment, other than the actual materials, is in the construction design – minimizing the amount of material used in the carcass construction without sacrificing structural integrity and durability.

Fitting cabinets in the van

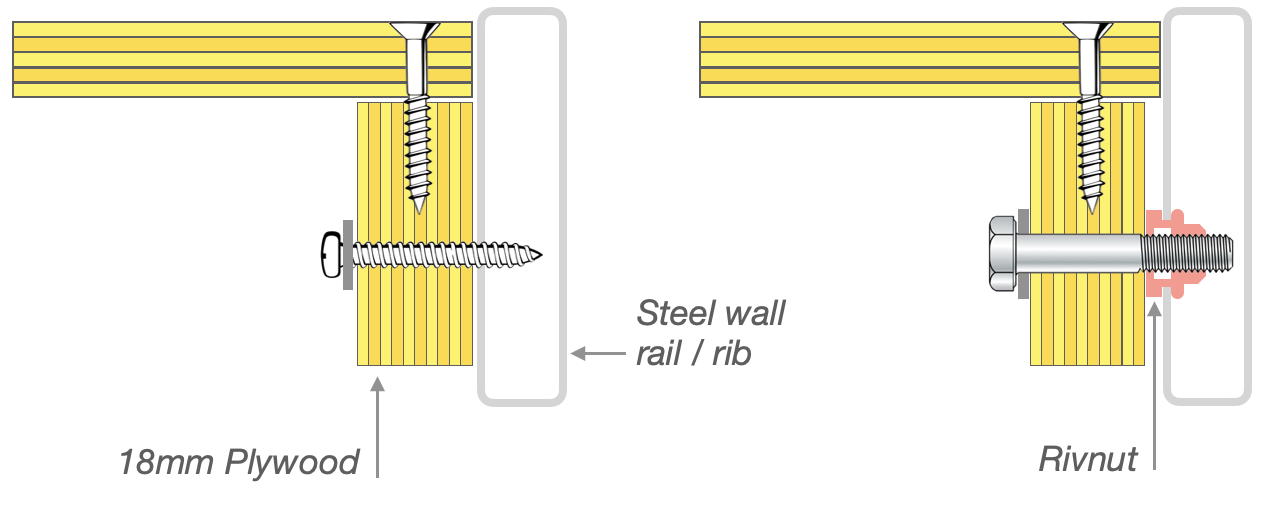

After you have built the cabinets, they must be attached to the body of the van. The cabinets need to be attached securely, but still have some ability to flex with the movement of the van, especially if regularly driving on rough tracks.

Van walls are rarely straight or ‘square’. So some adjustability (and often packing) is required for a neat fit. (There are plenty of videos available on YouTube with ideas and suggestions – not all ideal though!)

Neither are you likely to be able to use a spirit level for fitting battens, etc. This process will instead involve making an accurate measurement from the floor – which means that the very first step is fitting a durable floor. Again a good quality plywood, with a laminate flooring surface will make an ideal clean, flat base from which to work.

When it comes to installing battens to attach cabinets to the van walls, I would avoid using solid timber, especially cheap pine, which is likely to twist/warp/distort over time in a Campervan environment..

Aluminium channel is a light and sturdy option to form a batten for this purpose….

Alternatively, 18mm plywood will also do the job…

Rivnuts provide a robust ‘captive nut’ or ‘blind nut’ option, to secure a batten to a metal rail where the back of the rail may not be easily accessible to locate a nut.

Pre-drill screw holes in ply to avoid splitting, and apply a dab of silicone to the hole before inserting the screw, to prevent rattling loose over time – but keep the silicone out of the screw head so you can more easily remove the screw at a later date if necessary!

Other options for a ‘semi-DIY’ project ….. |

Door Latches & Hardware

Many cabinet construction and hardware items that are used in Campervans and Motorhomes have a history in the marine and boating environment.

Many cabinet construction and hardware items that are used in Campervans and Motorhomes have a history in the marine and boating environment.

Back in the day, the local Ship Chandlery was always a good place to have a browse for this sort of stuff, but these days specialist Campervan and Caravan parts suppliers stock a wide range of camper fit-out items.

Door latches are one such item. They need to be able to be easily opened and closed when in use, easily secured to prevent unintended opening when travelling, as well as being durable and corrosion resistant.

Here are some examples from a local online supplier:

DIY Fit-out | What size van? | Draw a floor plan | Cabinet materials | Fittings | 12V power

I was always under the impression that ‘lightweight marine ply’ was the only material to use when fitting out a Campervan.

I was always under the impression that ‘lightweight marine ply’ was the only material to use when fitting out a Campervan.