Sustainability: Batteries & Solar | Water | Heating

Batteries | Consumption | Battery Recharging | Solar Charging | How Long Without Sun? | Alternate Charging Options | Solar Regulators | The Bottom Line

See also: Lithium Battery Upgrade | Installing a Battery Monitor | Installing an Inverter

With a couple of extended trips on the horizon, we have taken the plunge and invested in 2 x 120Ah LiFePO4 (Lithium) batteries to replace our 2 x 100Ah AGM batteries.

With a couple of extended trips on the horizon, we have taken the plunge and invested in 2 x 120Ah LiFePO4 (Lithium) batteries to replace our 2 x 100Ah AGM batteries.

One battery, or two?

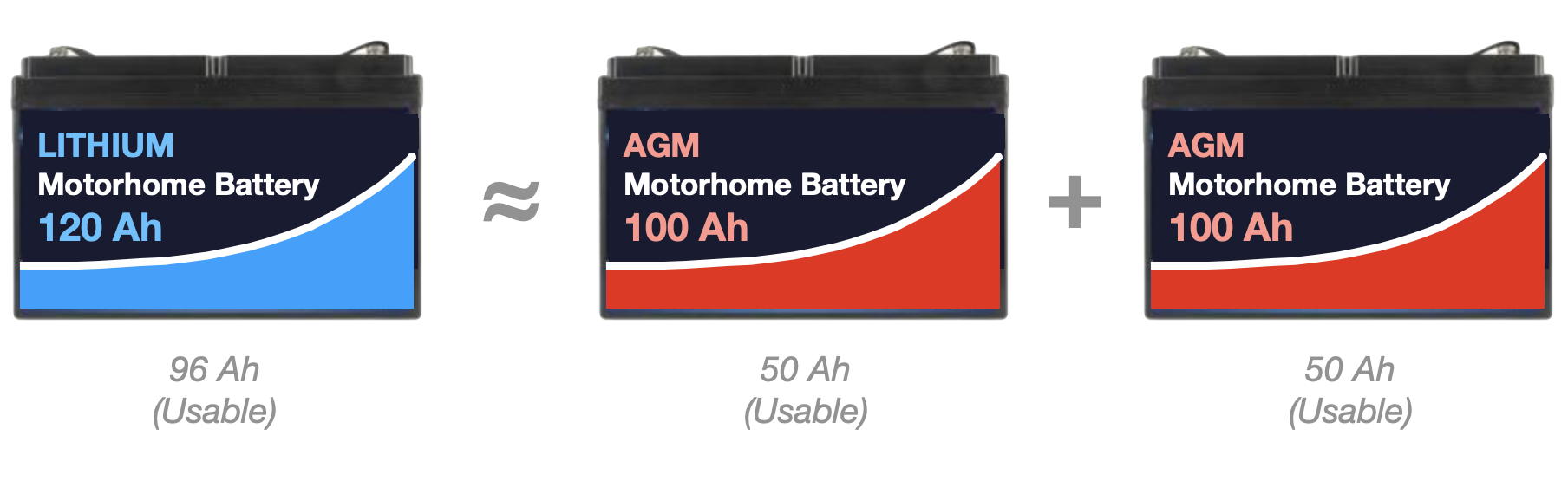

We could have saved some dollars by replacing our two 100Ah AGM batteries (total ‘usable’ capacity of 100Ah) with just one 120Ah Lithium battery (‘usable’ capacity of 96Ah).

One 120Ah Lithium battery would have provided around the same stored energy capacity as the two 100Ah AGM batteries, saved some weight and given us the Lithium advantage of steady and consistent voltage – a lot of effort, and expense, for a minimal gain. But let’s get real here …… if we are making the effort to go to the well, why come back with the bucket only half-filled?

By replacing two 100Ah AGM batteries with two 120Ah Lithium batteries (connected in parallel) we have almost doubled our off-grid 12V energy capacity (total usable capacity increased from 100Ah to 192Ah) while more than halving our battery weight (62kg down to 25kg).

Of course, if your van has only one AGM battery, and that single battery generally provides adequate energy resources for your needs, then replacing that one AGM battery with one Lithium battery will provide a significant advantage, in both weight and 12V free-camping longevity.

If you are fitting out a new van, and you are planning on spending nights where mains power is not available, it is a no-brainer – go for Lithium batteries.

Important: Battery Storage Update (2023)

These regulations apply to the installation of electrical equipment in vehicles and relocatable accommodation, and apply to the RV Industry. In relation to battery installation, all batteries must now be installed in storage closets, similar to those used to store LPG bottles. These closets must be sealed off from the interior living space and have external ventilation. In addition to the storage location, all Lithium batteries will be required to have a battery management safety system, located not less than 600mm from the battery, designed to prevent over-voltage, over-current and excessive temperature changes. All batteries must be protected from short circuits or over-current situations through the installation of fuses or circuit breakers. All cables connected to the battery terminals must be connected at the terminals provided by the battery manufacturer. No more than four cables can be connected to each battery terminal.

|

Taking Charge

Lithium batteries are relatively expensive, but they are not the only expense involved in a battery upgrade. AC-DC and DC-DC chargers also need to be considered, along with the battery monitoring system.

While some battery suppliers suggest that AGM batteries can be swapped out directly for their Lithium batteries without any other upgrades, I feel that this may be more sales pitch than honest engineering advice.

The battery management systems (BMS) built into most Lithium batteries may do a satisfactory job of modifying the voltage that is being supplied by an existing AGM charger to suit the preferred input voltage of Lithium batteries. However, I remain to be convinced that a BMS is able to adjust the overall charging stages of an AGM charger’s output to suit the specific charging requirements of Lithium batteries.

I would also expect that installing charging devices with a tailored Lithium profile will contribute to a better long term outcome for battery performance and lifespan. A bit like feeding an athlete on takeaway food rather than a healthy tailored diet – they will survive, but not reach their full potential. My opinion only, of course!

Our van was already fitted with a Lithium-capable Redarc 1240D DC-DC charger. All that was required to activate the Lithium profile was a change in the wiring at the rear of the charger – joining the green and orange wires.

Our van was already fitted with a Lithium-capable Redarc 1240D DC-DC charger. All that was required to activate the Lithium profile was a change in the wiring at the rear of the charger – joining the green and orange wires.

We replaced our AC-DC charger – a CTEK MXS 25 – with a CTEK M25 model that has a Lithium profile. The new charger is exactly the same size as the old charger (including mounting screw location) which made for a very easy replacement. Even better, the new charger auto-detected the Lithium batteries and adjusted itself appropriately.

Providing a neat conclusion to the upgrade process, a neighbour who was fitting out a van with a fridge for weekends away surfing purchased our AGM batteries and the AC-DC charger. This was a perfect setup for his needs, and a preferred outcome for us, avoiding a trip to the local recycling centre.

The Parallel UniverseCampervans and Motorhomes often have multiple batteries installed ‘in parallel’ to increase 12V electrical storage capacity.

Read more about connecting Campervan and Motorhome batteries in Parallel and in Series >>> |

Other considerations

Continuous discharge current: This is an important consideration if you will be running 230V AC appliances through a power Inverter. A small 2-slice toaster, for example, will pull a continuous 70 amps from your battery/s.

Continuous discharge current: This is an important consideration if you will be running 230V AC appliances through a power Inverter. A small 2-slice toaster, for example, will pull a continuous 70 amps from your battery/s.

Generally, a good quality 100Ah Lithium battery will be able to supply a continuous 100 amps of current, while a 200Ah Lithium battery will be able to supply around 200 Amps continuously. Some cheaper Lithium batteries have a lower continuous discharge capacity – around 50 amps for a 100 Ah battery.

Even with good quality batteries, I wouldn’t be keen to actually try discharging a battery at its maximum continuous discharge rate for an entire hour. Fortunately, the reality is that your toaster, microwave oven, coffee machine or hair dryer, connected to your battery/s through an inverter, will only be drawing continuous current at this rate for a minute or two.

Parallel battery connection can cumulatively increase the continuous current capacity of the battery bank. So, two batteries connected in parallel will double the continuous current availability of the individual batteries.

Check the specifications for the battery’s continuous/peak current discharge capacity, and the power requirements of any appliances that you may be running through an inverter.

-

- More info: Installing an Inverter in our Campervan

Recommended charging current: One of the claims made by Lithium battery suppliers is the ability of Lithium batteries to be able to recharge very quickly – often quoting the charge rate to be the same as the capacity of the battery – ie, around 100 amps for a 100Ah battery. This is a maximum rate for a very short period of time (5 secs). The recommended figure in the spec sheets is the one to look for, and understand, in relation to the charging current supplied by your battery charger. This figure is usually in the 20 amps – 50 amps range.

Recommended charging current: One of the claims made by Lithium battery suppliers is the ability of Lithium batteries to be able to recharge very quickly – often quoting the charge rate to be the same as the capacity of the battery – ie, around 100 amps for a 100Ah battery. This is a maximum rate for a very short period of time (5 secs). The recommended figure in the spec sheets is the one to look for, and understand, in relation to the charging current supplied by your battery charger. This figure is usually in the 20 amps – 50 amps range.

And of course, this range of input current will only be achieved when charging your batteries from the vehicle alternator or a 230V charger. A single solar panel will likely be supplying less than 10 amps in ideal conditions – in reality often much less.

Parallel balance: Batteries in a parallel setup must be the same capacity and age as each other. (Even, ideally, being from the same production batch, according to some battery gurus!) Before fitting the new Lithium batteries in our van we fully charged each battery separately (overnight on a 230V charger), so that they had the same level of charge when first connected.

Parallel balance: Batteries in a parallel setup must be the same capacity and age as each other. (Even, ideally, being from the same production batch, according to some battery gurus!) Before fitting the new Lithium batteries in our van we fully charged each battery separately (overnight on a 230V charger), so that they had the same level of charge when first connected.

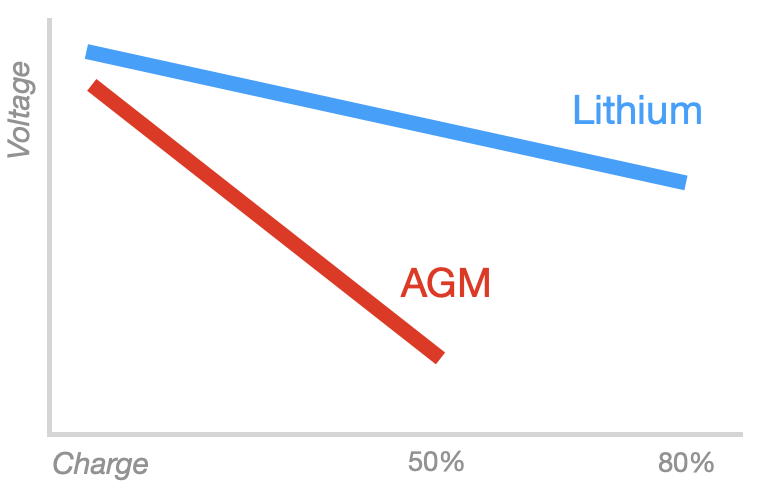

Battery Monitor: Our ‘control panel’ console initially had a voltmeter installed. A voltmeter is very much a standard option in most Campervans, and was OK for displaying the voltage of the AGM batteries, and in turn providing an estimate of the batteries’ State of Charge (SoC). However, the much smaller voltage drop of Lithium batteries over their discharge range makes a voltmeter impractical for determining the SoC of Lithium batteries.

Battery Monitor: Our ‘control panel’ console initially had a voltmeter installed. A voltmeter is very much a standard option in most Campervans, and was OK for displaying the voltage of the AGM batteries, and in turn providing an estimate of the batteries’ State of Charge (SoC). However, the much smaller voltage drop of Lithium batteries over their discharge range makes a voltmeter impractical for determining the SoC of Lithium batteries.

As part of the battery upgrade process we fitted a more comprehensive ‘Coulomb counter’ battery monitor, which is able to accurately measure the SoC, and many other parameters of Lithium batteries. (Be sure to calibrate your battery monitor to accurately reflect the capacity of your batteries.)

-

- See also: Installing a Battery Monitor >>>

Which battery?

There are plenty of Lithium batteries from which to choose these days. While budget is always going to be a consideration, I tend to keep in mind that quality will be remembered long after the price is forgotten.

There are plenty of Lithium batteries from which to choose these days. While budget is always going to be a consideration, I tend to keep in mind that quality will be remembered long after the price is forgotten.

After much looking around, comparing pricing and spec sheets, our choice came down to two batteries – iTechWorld 120Ah and Sphere 120Ah. Both were around the same price and had appropriate specs – particularly relating to their battery management system, cell construction, cell balancing, and continuous current draw (100+ amps – an important consideration if using an inverter).

At the time we were shopping, iTechWorld had a ‘show special’ promotion on their 120Ah battery, offering a $200 reduction on their regular pricing (of around $1000), which was very tempting. We spoke with a friend in the caravan fit-out business who has installed plenty of Sphere 120Ah Lithium batteries and recommends (and supports) them, and could supply them for the same price as the iTechWorld batteries. The local support aspect tipped the balance – we went with the Sphere batteries. (Friends have installed the iTechWorld batteries and are very happy with them too. Keep an eye out – the ITechWorld batteries are regularly ‘on special’. Not so the Sphere batteries, which I have never seen advertised, and are usually available through caravan parts supply outlets.)

Other Lithium battery options?

-

- Don’t bother with the China Cheapies on eBay. Reports suggest that the published specs don’t always match reality. They will end in tears – or at least disappointment.

- Redarc (and other reputable brands) had 120Ah batteries for around $2000, but we couldn’t see enough difference in their specs, when compared to the $1000 batteries (from other equally reputable local suppliers), to justify the cost;

- At the other end of the spectrum (at the time we were shopping), Aussie Batteries had a 120 Ah ATLAS brand battery for $549, but digging into the specs they come up short in their maximum continuous current rating, at 60A. Ditto for VoltX at 50A (sometimes available through Aldi). These batteries will struggle with the demands of high-power appliances running through an inverter – but they may be just fine if you don’t need to run appliances with a high continuous current demand;

- Cheaper batteries may be built using cylindrical cell technology, rather than the more recently developed prismatic cells, which are generally lighter and smaller for the same output.

- (Update) For a lower cost option, check out this video review of the Kings Lithium battery, from Aussie Arvos.

Cabling tidy up

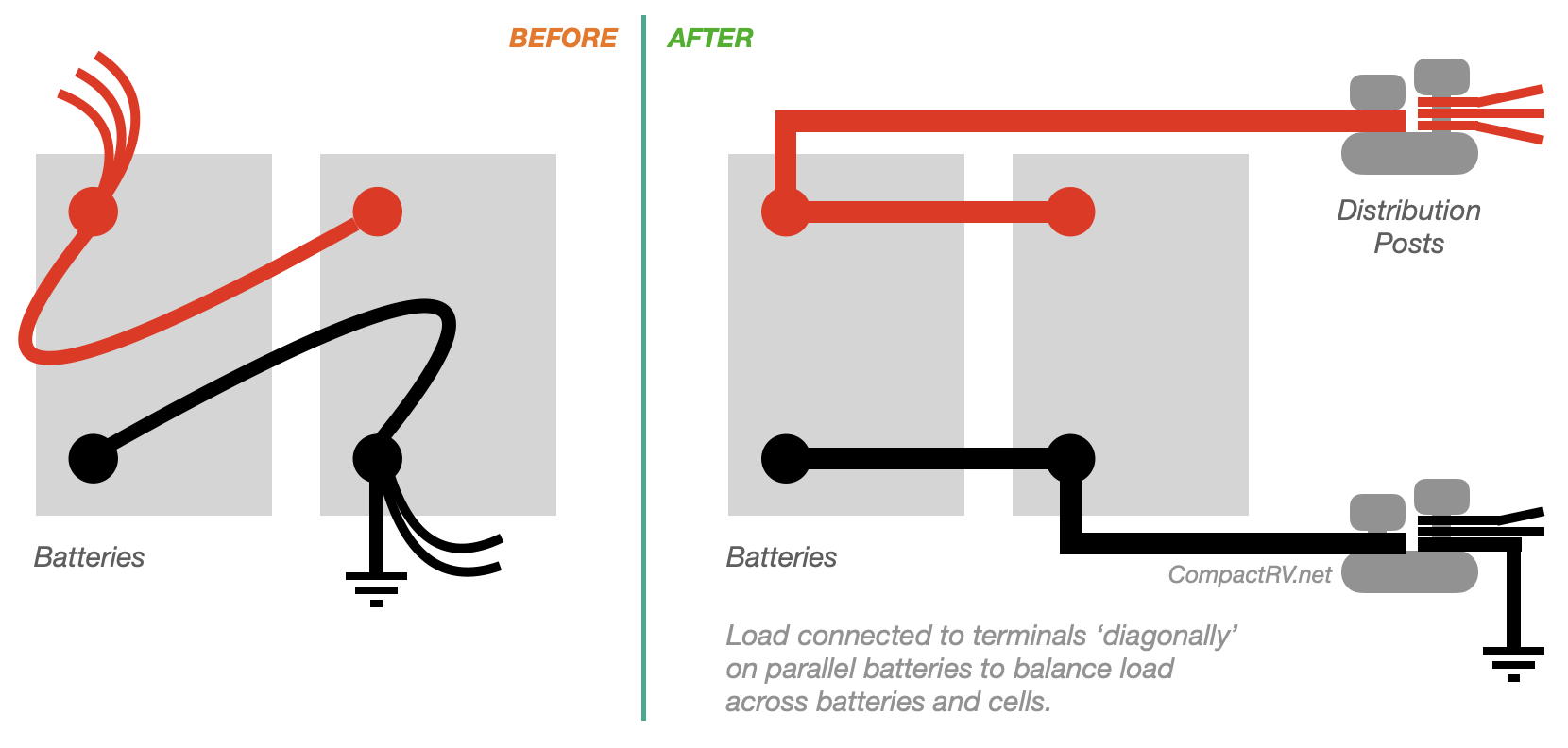

The battery swap also provided an opportunity to tidy up our battery cabling.

We replaced the existing cables between the parallel batteries – 6 B&S (16 mm²), 600mm long – with heavier and shorter cables – 2 B&S (32 mm²), 250mm in length. We also installed a couple of dual distribution posts adjacent to the batteries (Jaycar, $12). All appliance and charger cabling is now connected to the distribution posts, which are connected to the batteries with heavy gauge (2 B&S) cables. These cables are readily available in various lengths in the battery section of your local auto parts store for around $20. Though for some unknown reason, red cables are difficult to find in auto stores. Black and blue seem to be the popular colours.

Battery Storage

-

- Note: New Australian Design Rules regarding the storage of batteries in Campervans and Motorhomes have been introduced since the information below was published. Refer to the update panel above.

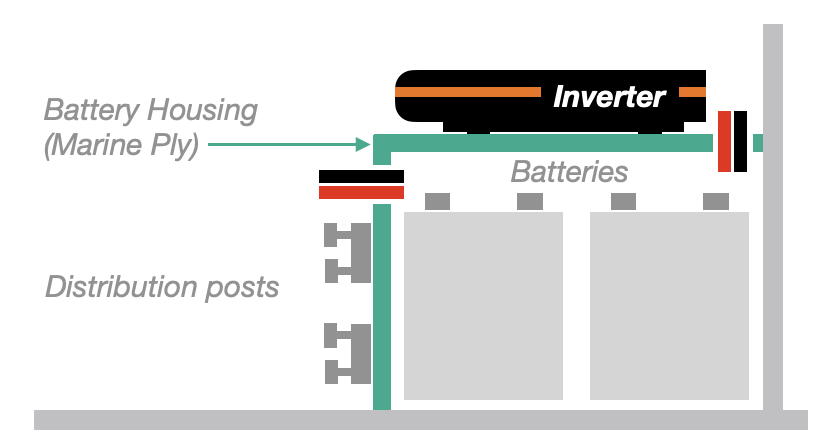

Our original AGM batteries were contained in two plastic battery boxes. We have replaced these boxes with a much sturdier and tidier laminated marine ply housing. The batteries are secured to the chassis with polyester seat belt webbing and a clamping bracket. Sturdy foam packaging material fitted between the batteries and the chassis provides for shock absorption on rough roads.

The cable distribution posts mounted adjacent to the battery housing provide much easier access to existing cabling connections, and will simplify the connection of any additional cabling in the future, without requiring direct access to the battery terminals.

The marine ply battery housing also provided a solid platform on which to mount a new power inverter, in an ideal location close to the batteries.

First impressions – what we are noticing so far….. |

Weight: The first and most obvious observation is the weight of the batteries. Quite amazing. The AGM batteries weighed 31 kg each – what a difference when installing the 12 kg Lithium batteries….

Weight: The first and most obvious observation is the weight of the batteries. Quite amazing. The AGM batteries weighed 31 kg each – what a difference when installing the 12 kg Lithium batteries….

-

- AGM batteries: 2 x 31 kg = 62 kg

- Lithium batteries: 2 x 12.5 kg = 25 kg

- The Lithium installation is 37 kg lighter.

- Net result: We have a 37 kg increase in payload capacity. We will no doubt soak that up with other items – eg, we recently purchased a steel flat-pack fire pit that checks in at 18 kg. I will be looking forward to a visit to the local weigh-bridge when we are loaded up for our next trip.

Battery monitor: The voltage output from an AGM battery declines at a linear rate, and reflects the State of Charge (SoC) of the battery. This relationship can be used in conjunction with a voltmeter to provide an estimate of the SoC of an AGM battery. This isn’t practicable with Lithium batteries, as their voltage remains reasonably constant across their discharge period.

Battery monitor: The voltage output from an AGM battery declines at a linear rate, and reflects the State of Charge (SoC) of the battery. This relationship can be used in conjunction with a voltmeter to provide an estimate of the SoC of an AGM battery. This isn’t practicable with Lithium batteries, as their voltage remains reasonably constant across their discharge period.

-

- We have fitted a new battery monitor – a Coulometer – that calculates the remaining charge in the batteries (measured in Coulombs) by measuring the current moving into and out of the batteries;

- This monitor displays battery voltage, amps in, amps out, remaining Ah, and % charge remaining;

- Net result: This is excellent. We now have a battery monitor that provides far more information than a simple voltmeter. We should have installed one of these monitors years ago! (These monitors will also work with AGM batteries.)

-

- See also: Installing a Battery Monitor >>>

Discharge period: The battery monitor indicates that the Lithium batteries are discharging around 27 Ah between 6:00 pm and 6:00 am, with only the fridge running overnight.

Discharge period: The battery monitor indicates that the Lithium batteries are discharging around 27 Ah between 6:00 pm and 6:00 am, with only the fridge running overnight.

During the following (mostly sunny) days (in Autumn on the NSW South Coast) the batteries regain around net 13 Ah from the 150W rooftop solar panel (with the fridge still running), creating a net 24 hour deficit of 14 Ah.

The maths says that at 14 Ah net consumption per (sunny autumn) day, our 192 Ah usable battery capacity will sustain us for nearly 2 weeks, without any other form of charging.

-

- The Lithium batteries will power our appliances for much longer than the AGM batteries in a free-camping environment, simply by virtue of their higher usable capacity;

- The total usable battery capacity available from our 2 x 100 Ah AGM batteries was 100 Ah (based on 50% discharge);

- The total usable battery capacity available from our 2 x 120 Ah Lithium batteries is 192 Ah (based on 80% discharge);

- That is nearly double the usable capacity of our 100 Ah AGM batteries;

- Our appliances consume around 70 Ah per day. Mainly the fridge;

- In theory, with zero charging, the AGM batteries could power our appliances for around 1.5 days;

- With similar (theoretical) zero charging conditions the Lithium batteries can power the same appliances for 2.7 days;

- With reasonable solar charging each day during Autumn we are seeing a 24hr deficit of around 14 Ah. This will give us over 10 days of power, using only the 150W roof-top solar panel to provide recharge current during the day;

- With our 200W solar blanket added to the mix I expect that we would eliminate the re-charging deficit and fully power a free-camp environment for far longer than I expect we would be likely to stay in any one location;

- Water supply (and toilet cassette) capacity will now be of much greater concern than electricity supply for free-camping. Carrying more water means more weight – unlike the Lithium batteries that supply double the AGM energy storage capacity for half the weight!

- Net result: We haven’t yet had an opportunity to check the 10+ days capacity in a real camping environment, but after 5 autumn days and 6 nights parked in the driveway with the fridge running 24/7, charging only from the 150W solar panel, the batteries are at 130Ah, or around 55% capacity. And the voltmeter remains around 13.0 volts. Certainly for a few days free-camping there will be no need to be checking the battery voltage every few hours. The Lithium batteries will last longer than we are likely to be free-camping without starting the engine. Next we will need to figure out the provision of a renewable water supply!

Re-charging: In theory, (and that is a big ‘in theory’) Lithium batteries are able to re-charge much more quickly than AGM batteries. Lithium batteries can charge continuously at a rate (amps) of up to 50% of their rated capacity (Ah) while AGM batteries are limited to a re-charge current of up to 20% of their capacity.

Re-charging: In theory, (and that is a big ‘in theory’) Lithium batteries are able to re-charge much more quickly than AGM batteries. Lithium batteries can charge continuously at a rate (amps) of up to 50% of their rated capacity (Ah) while AGM batteries are limited to a re-charge current of up to 20% of their capacity.

-

- Lithium batteries achieving significantly faster charging depends on a relatively high rate of charging current. A bit of a moot point if your solar panels are producing only a small amount of current that doesn’t take advantage of the potential higher recharge current capacity;

- The reality is that with only 6 amps input from our 150W solar panel, 2 to 3 amps of which is consumed by the fridge, there will be very little noticeable reduction in the re-charge time of the Lithium batteries compared to AGM batteries when charging from the solar panel;

- With higher current input from the vehicle alternator or the 230V charger, the Lithium batteries are likely to recharge more quickly than AGM batteries when these sources are generating current;

- The battery monitor indicates that, when plugged in to power, the CTEK M25 AC-DC charger is feeding 25 amps into the batteries. When the engine is running, the vehicle alternator is pushing 40 amps into our energy storage, even when idling. The alternator charge rate is governed by the Redarc 1240D charger.

- Net result: Without any re-charging, the 2 x 120Ah Lithium batteries will power our appliances for nearly twice as long as the 2 x 100Ah AGM batteries. Electrical current generated by the solar panel/s will considerably extend this period of time when we are off the grid. The vehicle’s alternator appears to re-charge the Lithium batteries a little more quickly than the AGM batteries, but I am not able to easily verify that assessment.

Appliance options: The Lithium batteries have given us the opportunity to install an inverter, to power 230V AC appliances from the 12V DC batteries. We can now pull up for lunch at a beach carpark or roadside rest area and pop a couple of toasties in the sandwich press.

Appliance options: The Lithium batteries have given us the opportunity to install an inverter, to power 230V AC appliances from the 12V DC batteries. We can now pull up for lunch at a beach carpark or roadside rest area and pop a couple of toasties in the sandwich press.

-

- Lithium batteries are able to supply a high level of continuous current, compared to AGM batteries;

- The Sphere Lithium batteries can supply a continuous 100 amps each. This provides around 180 – 200 amps with the two batteries connected in parallel;

- A couple of toasties in the sandwich press for lunch pulls current at the rate of around 97 amps, draining 5Ah from the batteries’ storage;

- 10 mins of driving recharges the current used for the toasties!

- Net Result: Appliances such as a toaster, sandwich press, coffee machine, hair dryer – even the microwave oven – are now able to be used when mains power is not available. This certainly takes us to the next level of glamping!

Voltage: After testing the Lithium batteries for five consecutive days and nights, with the fridge running with no charging other than the 150W solar panel, the voltage hasn’t dropped below 13.0V.

Voltage: After testing the Lithium batteries for five consecutive days and nights, with the fridge running with no charging other than the 150W solar panel, the voltage hasn’t dropped below 13.0V.

-

- AGM batteries drop from 12.8 to 12.1 volts over their 50% discharge period.

- Lithium batteries drop from 13.5 to 12.6 volts over their 80% discharge period.

- After running the fridge all night for consecutive nights, the Lithium batteries are still maintaining 13.2V first thing in the morning, compared to around 12.3 V for the AGM batteries.

- Net result: Our fridge is likely to maintain a more reliable temperature over a longer period of time, and will use slightly less current when operating at a higher voltage.

Life cycle: The label on the new Lithium batteries indicates that they have a minimum 2000 charge cycles – which will last us forever! Well, maybe not forever, but longer than the AGM batteries.

Life cycle: The label on the new Lithium batteries indicates that they have a minimum 2000 charge cycles – which will last us forever! Well, maybe not forever, but longer than the AGM batteries.

-

- AGM batteries are able to be discharged / recharged around 500 times over their life span, if not discharged to below 50% capacity.

- Lithium batteries have at least 2000 recharge cycles if not discharged below 20% capacity. (Up around 6000 cycles if discharged to only 50%.)

- Net result: Hopefully the new batteries will maintain their performance for 10 or more years, so I will feel better about the high up-front cost. However, I am not so naive to think that there won’t be something bigger and better available by then!

See also: Lithium Battery Upgrade | Installing a Battery Monitor | Installing an Inverter

|

More reading:

|

Batteries | Consumption | Battery Recharging | Solar Charging | How Long Without Sun? | Alternate Charging Options | Solar Regulators | The Bottom Line

New Australian Design Rules for ‘Connectable Electrical Installations’ were released in November 2022. (Australian Standards AS/NZS 3001.2:2022).

New Australian Design Rules for ‘Connectable Electrical Installations’ were released in November 2022. (Australian Standards AS/NZS 3001.2:2022).