Sustainability: Batteries & Solar | Water | Heating

Batteries | Consumption | Battery Recharging | Solar Charging | How Long Without Sun? | Alternate Charging Options | The Bottom Line

See also: Solar charging reality | Battery charging basics | Install a battery monitor

Making the Right Connections

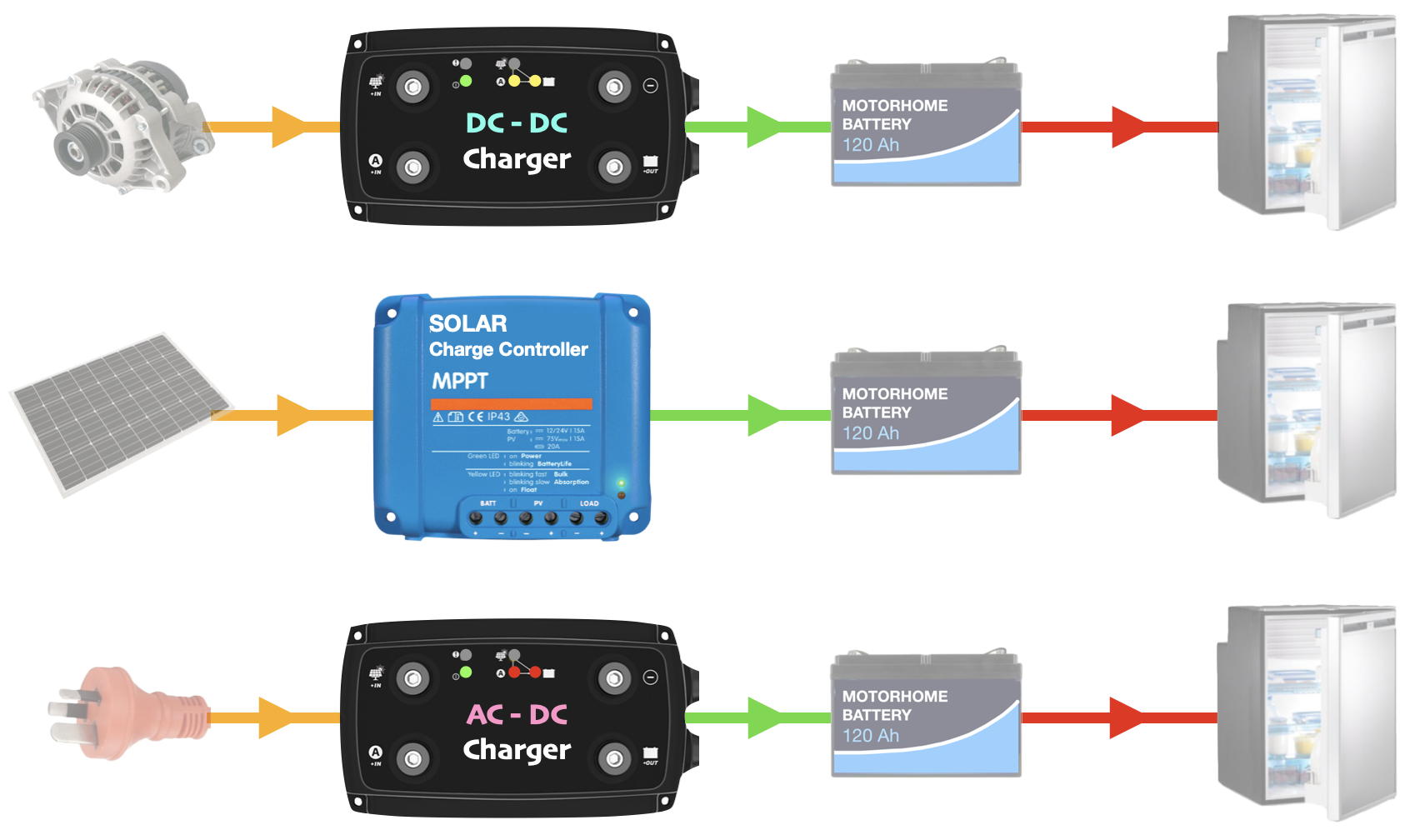

Deep cycle batteries in Campervans and Motorhomes are able to be recharged from the vehicle alternator, solar panels or a 230V mains supply.

But not directly.

The charging current feeding to the batteries from the vehicle alternator, solar panels or mains supply MUST be regulated and controlled by a battery charger/regulator….

Fortunately, modern battery chargers make battery charging a relatively straightforward process.

DC-DC & Solar Combo Chargers: Redarc BCDC40 | CTEC D250E | Kickass Chargers

The Modern Battery Charger

While it is possible to install a separate DC-DC battery charger for each DC (Direct Current) charging source (as shown in the image above), most modern battery chargers designed for use in a Campervan or Motorhome environment will accept and regulate DC input from multiple sources, and feed appropriately regulated DC charging current to the batteries. Consequently only one charger is required for DC current sources – typically solar panels and the vehicle alternator.

While it is possible to install a separate DC-DC battery charger for each DC (Direct Current) charging source (as shown in the image above), most modern battery chargers designed for use in a Campervan or Motorhome environment will accept and regulate DC input from multiple sources, and feed appropriately regulated DC charging current to the batteries. Consequently only one charger is required for DC current sources – typically solar panels and the vehicle alternator.

A separate charger is still usually installed for AC (Alternating Current) mains power charging, though this too is changing, with some recent chargers catering for both AC and DC input sources (not cheap though!).

Two schools of thought here….

-

- Install only one charger – less opportunities for something to go wrong;

- Install multiple chargers – avoid single point of failure.

Putting it all together

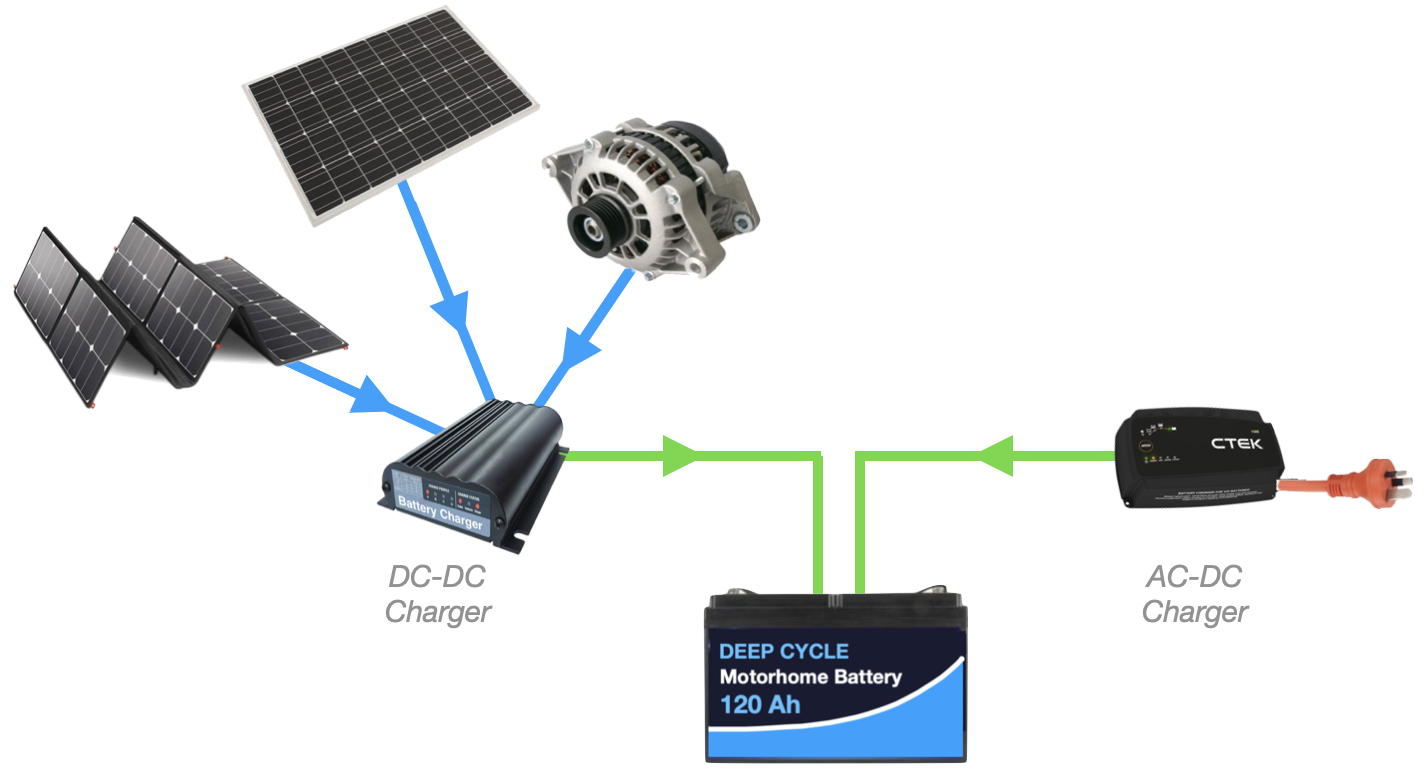

The two ‘house’ batteries in our van can be recharged by electrical current generated from multiple sources….

-

- a solar panel on the roof of the van;

- a portable solar panel / blanket;

- the vehicle alternator, when the engine is running;

- 230V, when connected to a mains power supply.

Each of these charging sources are connected to the batteries via an appropriate battery charger/regulator – a dual-input DC-DC charger for electrical current from the solar panels and alternator, and an AC-DC charger for electrical current from a 230V power supply.

These chargers monitor and regulate the charging voltage and current flowing to the batteries, adjusting this voltage and current to suit the batteries’ State of Charge (SoC).

In particular, a dedicated charger/regulator ensures appropriate voltage and current flowing from the vehicle alternator (usually increasing it from the default alternator output), and isolates the ‘house’ appliances and circuits from the vehicle’s starting battery and associated electrics.

We have three DC charging sources connected to our Redarc 1240D BC-DC charger:

-

- A 200W solar panel – mounted permanently on the roof. This panel regularly generates around 8-10 Amps during the day (much less when it is cloudy, or early in the morning or late in the afternoon) restoring up to 10Ah per hour to the batteries. Of course this is very much dependent on the weather conditions, the time of day, and the angle of the panel to the sun. (I have seen outputs as high as 12A in the middle of the day);

- A 200W solar blanket – portable, connects to the Redarc DC-DC regulator via an Anderson plug under the side of the van. A good quality 200W blanket can (theoretically) generate up to 10 Amps, restoring up to 10Ah per hour to the batteries, again depending on weather conditions, etc. A portable solar blanket or panel can be moved during the day to track the sun. (Our blanket is a ‘cheapie’, and outputs a maximum of only around 6 Amps – restoring up to 6Ah per hour to the battery/s, which is all we really need to supplement the 200W roof panel.)

- The vehicle alternator – feeds 40 Amps to the batteries, even when idling. This will restore 40 Ah per hour to the batteries’ stored energy. (This rate of current is dependent on the specification of the battery charger);

We can also charge our batteries from a 230V AC mains supply:

-

- Our AC-DC charger (CTEK M25) is rated at 25 amps and feeds around 22 amps into the batteries when plugged into mains power at a campground, restoring 22 Ah per hour to the batteries’ stored energy. This charger kicks in automatically when the van is connected to a mains supply.

-

- Case Study: 12V Charger Cabling – Get it right >>>

Old-school isolators

Modern dual-input battery chargers have this functionality built-in. The electrical systems in older Campervans often achieved this isolation environment using a simple manual switch – pull up to camp for the night and turn the switch to the off position to isolate the starter battery. Then came automatic electrical-switching isolators that used diodes to allow charging current to flow from the alternator to both the starter battery and the auxiliary battery, but prevented camping appliances draining current from the starter battery. More electronically advanced isolators such as Voltage Sensitive Relays (VSR) brought more ‘smarts’ to the battery isolating process, but are still nowhere near as effective or efficient as a dedicated battery regulator/charger. The basic ‘isolating’ functionality of all these devices allows charging current to flow from the alternator to the auxiliary battery/s when the engine is running, while preventing camping appliances such as fridges from depleting the storage capacity of the vehicle’s starter battery. While these devices do feed charging current to the house battery/s, they do so at a very basic level, feeding constant current directly from the alternator to the battery/s, with little adjustment (if any) of the current and voltage to suit the specific charging requirements of deep cycle batteries. Older isolating units were barely suitable for charging AGM batteries (risking long term damage to the batteries and/or the alternator), but are definitely not suitable for charging Lithium batteries. To make all this even more complicated, modern temperature-controlled and ‘smart’ alternators (post 2006) will respond to under-bonnet temperatures and drop their output voltage to protect the electrics of the alternator and the vehicle starter battery, rather than responding to the charging requirements of the remote auxiliary / accessory battery, resulting in an auxiliary battery that may never fully charge. This ‘smart alternator’ issue is overcome by installing a dedicated battery charger/regulator. For more general info about options for charging auxiliary batteries it is worth watching the videos in the links at the bottom of this page. Note: Battery charging isolators are still available, some with built-in ‘smarts’. They are often used for basic DIY dual battery setups in 4WD and commercial vehicles, but are not really suitable for use in modern Campervans and Motorhomes, especially when compared to dedicated DC-DC chargers. |

Which charger for your batteries?

Different charging regimes are required to suit the different chemistries of AGM and Lithium batteries. Many modern chargers – but not all – can switch between output modes to suit these differing requirements…..

Recharging AGM Batteries

AGM batteries should be recharged before they reach their 50% discharge level (12.1V, measured with no load or charging).

AGM batteries should be recharged before they reach their 50% discharge level (12.1V, measured with no load or charging).

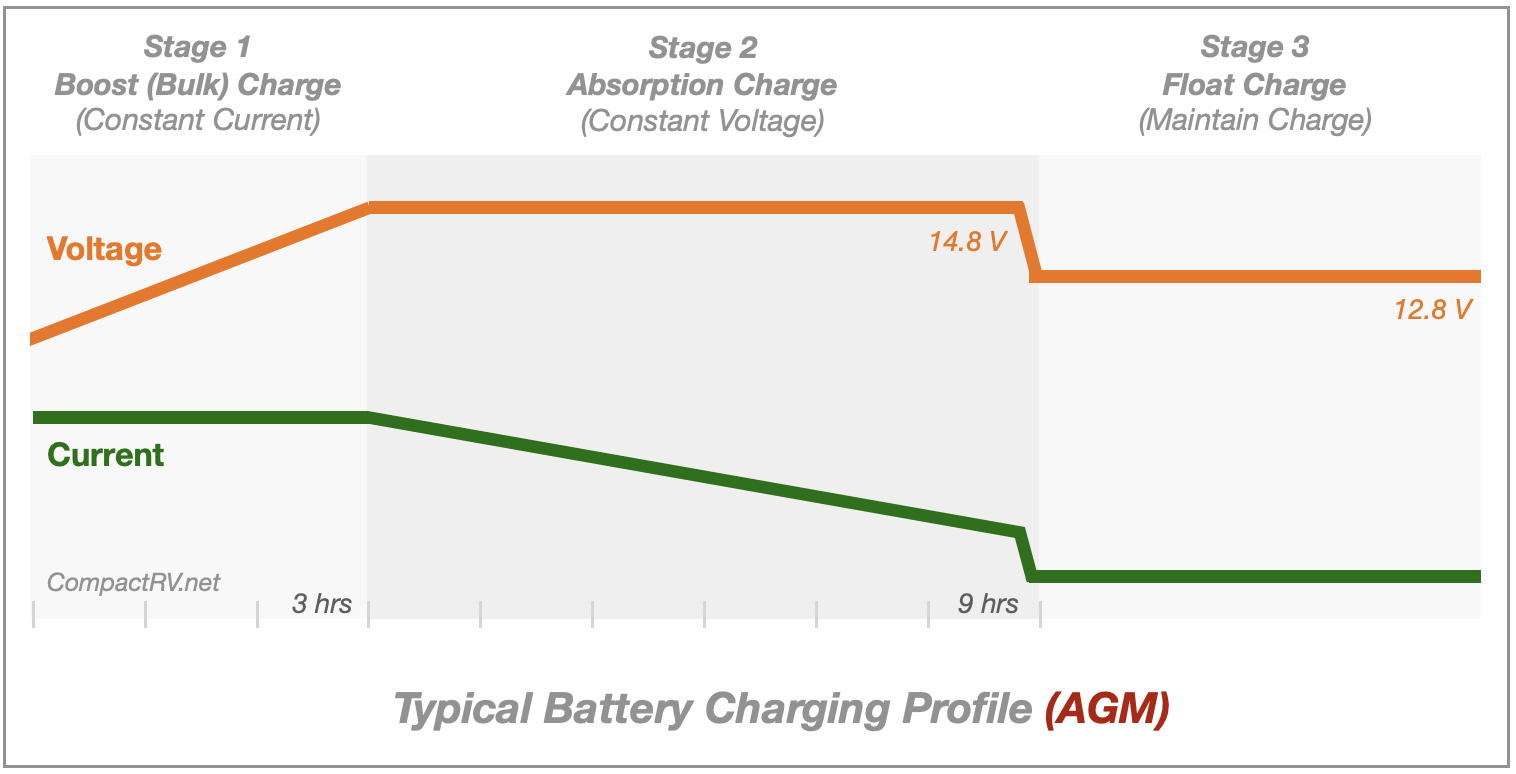

While deep discharging of AGM deep cycle batteries to below 50% SoC should be avoided, so too should overcharging. Both the AC-DC and DC-DC chargers regulate the charging of AGM batteries in three phases – regardless of the input source:

-

- Boost (aka Bulk) charging – progressively increasing voltage to maximum capacity, with limited but constant current charging rate;

- Absorption charging – maintaining constant maximum charging voltage, current steadily reducing;

- Float charging – ‘trickle’ current charging to maintain optimum operating voltage.

Sounds complicated!

Fortunately, this charging process is monitored and managed by your battery charger….

-

- Stage 1 (Boost or Bulk charge): A constant charging current up to 30% of the battery’s rated capacity is provided by your charger until the battery voltage reaches 14.6V at around 70% of the overall battery charge (up to 4 hours)*;

- Stage 2 (Absorption charge): Above 70% charge capacity the charging current is gradually reduced by the charger, maintaining a constant voltage (around 14.6V), as the battery’s SoC moves towards maximum charge (up to 6 hours)*;

- Stage 3 (Float charge): When the battery reaches its fully charged capacity, the charger provides a ‘trickle’ current flow to maintain the battery at its optimum operating voltage (around 13.5V when float charging).

Battery chargers also adjust the voltage supplied to the batteries. For example, the output from most solar panels is around 18V, while the charging input for most AGM batteries is around 14.6V. Your DC-DC charger adjusts this voltage automatically to protect your batteries. (You shouldn’t connect a solar panel directly to your batteries!)

Good quality MPPT chargers harness this excess solar panel voltage to increase the current charging the batteries.

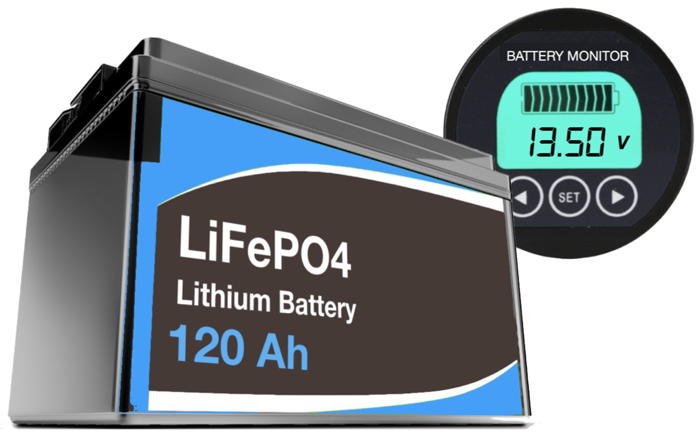

Recharging LiFePO4 (Lithium) Batteries

Lithium batteries require a slightly different charging algorithm to AGM batteries. Your battery charger should have a Lithium charging profile to correctly charge LiFePO4 batteries.**

Lithium batteries require a slightly different charging algorithm to AGM batteries. Your battery charger should have a Lithium charging profile to correctly charge LiFePO4 batteries.**

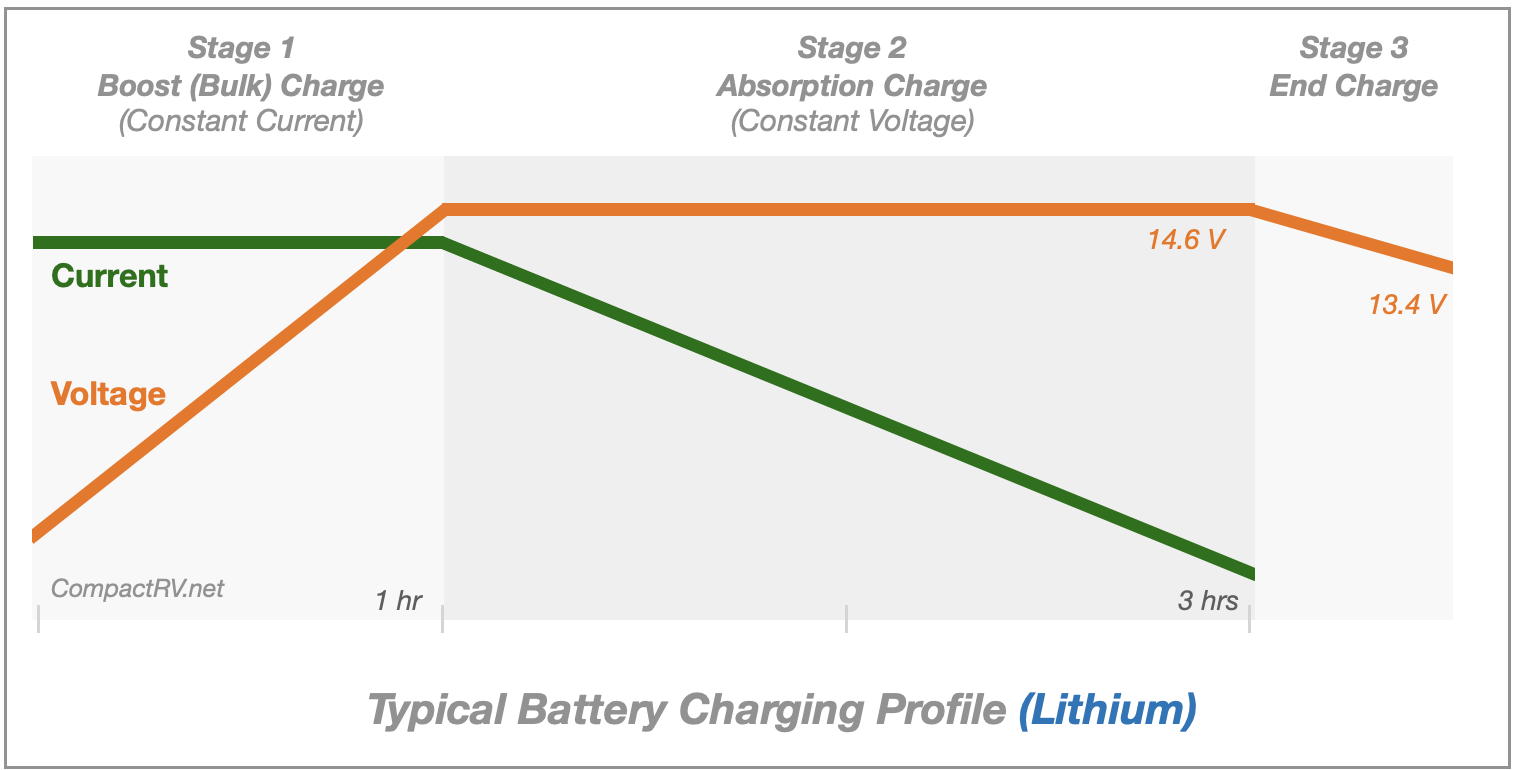

Essentially Lithium batteries have a two stage charging profile, rather than the three stage profile of AGM batteries.

While maintaining a roughly similar charging profile as AGM batteries for the first two stages (see graphs above and below), LiFePO4 batteries are able to charge at a much higher rate in the initial Boost mode – current input can be a constant 30 – 50 amps. This can result in a much faster recharge time, if you have sufficient current input*. AGM batteries might take 3-4 hours to process the Boost stage, while a LiFePO4 battery can complete the same stage in just 1 hour – with a high enough input current*.

If you read the spec sheets and information from retailers and suppliers, you will be advised that in Absorption mode an AGM battery might take 10 hours to reach full capacity, while an equivalent size Lithium battery can complete this stage in anything from 30 minutes to 2 hours.

This may be true in some circumstances, but this only occurs if there is enough current feeding into the battery (30 – 50 amps). In the world of Campervan reality, with only around 6 amps input from a 150W solar panel, and a fridge drawing around 2 – 3 amps of that current, a Lithium battery will still take most of the day to fully recharge if a solar panel is the only charging source, and it is in full summer sunshine.

Our experience (in Autumn) is that the 150W solar panel feeding into Lithium batteries – with the fridge continuing to consume current all day – recharges about half of what was consumed the previous night. So every night we are consuming 30 Ah, but only replenishing a net 15 Ah the following (sunny) day, over and above the fridge consumption (30Ah during the day also). This is where an additional portable panel can really help the recharge time.

Still, with 192 Ah of ‘usable’ energy available (80% of 240 Ah), a deficit of 15 Ah per day gives us 12 or so days of solar-supported electrical energy before we need to recharge from another source. And during this time the batteries rarely dip below 13V. In reality it is unlikely that we will stay in the same place for more than 10 days without starting the van – maybe to go get some drinking water – which is when the alternator charging kicks in at 40 amps.

With no load, LiFePO batteries are able to maintain their charge for many months, and don’t require a Float stage to compensate for any auto-discharge. In fact, Lithium batteries prefer (and will have a longer life-cycle) if charged to 70% when not being used for any length of time, rather than continually being topped up at 100%.

Can I recharge Lithium batteries with an AGM charger?

While some Lithium battery suppliers claim that AGM batteries can be swapped out directly for their Lithium batteries without upgrading your battery charger/s, I feel that this may be more sales pitch than honest engineering advice.

While some Lithium battery suppliers claim that AGM batteries can be swapped out directly for their Lithium batteries without upgrading your battery charger/s, I feel that this may be more sales pitch than honest engineering advice.

The battery management systems (BMS) built into most Lithium batteries may do a satisfactory job of modifying the output voltage of an existing AGM charger to suit the preferred input voltage of new Lithium batteries. However, I remain to be convinced that a BMS is able to adjust the overall charging stages of an AGM charger’s output to suit the specific charging requirements of Lithium batteries.

Yes, AGM chargers will work. But I expect that installing charging devices with a tailored Lithium profile will contribute to a better long term outcome for battery performance and lifespan. A bit like feeding an athlete on takeaway food rather than a healthy tailored diet – they will survive, but not reach their full potential. My opinion only, of course! (See links in the ‘More info’ panel below.)

DC-DC Chargers: Redarc BCDC40 | CTEC D250E | Kickass Chargers

* Faster recharge times will be more noticeable with higher current inputs, from sources such as the vehicle alternator or a 230V charger. A few amps feeding in from a 200W solar panel, while a fridge is drawing current, may not necessarily result in too much difference in the re-charge times between AGM and Lithium batteries.

** LiFePO4 batteries have a built-in Battery Management System (BMS) that some manufacturers claim allows their battery to be charged using a regular AGM battery charger. Or even a Voltage Sensitive Relay (VSR) connected to the vehicle alternator. The BMS is claimed to be able to modify the output from an AGM charger or VSR to suit the charging profile required for efficient re-charging of Lithium batteries. I take this claim with a grain of salt! Still early days, so no real knowledge of how these systems might impact on the overall performance or long-term life of Lithium batteries.

The next section – Solar Charging – discusses how much energy is recharged to the batteries from our roof-top solar panel and solar blanket.

More info…

Kings Dual Battery Masterclass (Videos)Redarc – Charger optionsCharger reviews – videos

|

Batteries | Consumption | Battery Recharging | Solar Charging | How Long Without Sun? | Alternate Charging Options | The Bottom Line

If you have a dual-battery setup – a ‘starter’ battery to start your vehicle engine, and a ‘deep-cycle’ auxiliary battery to run your fridge, lights, etc. – and you are using the vehicle alternator to charge both batteries – then you need to ‘isolate’ the house electrics from the starter battery, so that electrical appliances used for camping can only draw current from the deep-cycle auxilliary battery, so running the fridge all night doesn’t flatten your vehicle starter battery.

If you have a dual-battery setup – a ‘starter’ battery to start your vehicle engine, and a ‘deep-cycle’ auxiliary battery to run your fridge, lights, etc. – and you are using the vehicle alternator to charge both batteries – then you need to ‘isolate’ the house electrics from the starter battery, so that electrical appliances used for camping can only draw current from the deep-cycle auxilliary battery, so running the fridge all night doesn’t flatten your vehicle starter battery.