<<< DIY Campervan Mini Projects

Swytch e-Bike Conversion – Background Info

Road Bike Conversion | Mountain Bike Conversion

Not strictly a Campervan DIY project, but we know that many in the Campervan community have been exploring e-Bike options – including us!

Weight and cost restrictions saw us head down the DIY e-Bike path. These pages are a summary of our DIY e-Bike installation and riding experience.

Planning for an eBike Conversion – Is it worth it? |

||

|

If you are a casual rider, looking at e-Bike options, you can buy a basic pedal assist e-Bike for not much more than the cost of a Swytch conversion kit. (Eg – see Leitner bikes.) So, if you have an old steel bike gathering rust in the shed, and your cycling needs are modest, check out the ready-made options rather than a conversion. We have been riding bikes fitted with Swytch kits (Gen 3 Max) for a couple years, and they are perfect for our needs. These are considered to be ‘hybrid’ bikes – they require pedalling to activate the motor. If a hybrid / pedal-assist bike suits your cycling needs, and you don’t have a good quality regular bike sitting in the garage ready to be converted, then go shopping for an off-the-shelf eBike, either new or used. There are plenty available these days. Different story if you already have a good quality bike. If you do go shopping for an e-Bike, there are some important options to consider – most notably the choice between a pedal-assist ‘hybrid’ bike, or a full e-Bike – with a larger battery, a more powerful motor, and a throttle, etc. (Also be aware that e-Bikes with large motors and throttles, and capable of speeds higher than 25 kph, are not able to be legally ridden on public roads and pathways in most Australian states.) Many ‘entry-level’ e-Bikes are also very heavy – around 25kg. If shopping for a new e-Bike, similar to what you will end up with if you convert a regular road bike to a pedal-assist bike, the Merida eSpeeder is an excellent example. This is a true ‘hybrid’ bike (rather than an ‘electric motorbike’), weighing in at around 15kg. There are of course similar bikes available from other manufacturers. Having said all that, we went down the DIY hybrid path, converting our existing carbon-frame road bikes (and subsequently our mountain bikes) to ‘pedal-assist’ bikes. From a cost perspective, we converted our two carbon-frame bikes to hybrid pedal assist e-Bikes for less than the cost of one of the Merida eSpeeder bikes mentioned above. Our converted road bikes each tip the scales at around 15kg, an important consideration for loading the bikes on our Campervan’s bike rack. Another important consideration for us was the mounting of the Swytch battery on the handlebar, which doesn’t consume frame space that we use for bottles and bags when touring. Read on for more information about our e-Bike conversion journey…. |

| See also… | Download…. |

|

|

| Kiama Bicycle Users Group | Swytch OLED Quickstart Guide |

Batteries everywhere!We have enjoyed our battery-powered bikes so much

|

e-Justification

We cycle regularly to help maintain a level of physical health and fitness – along with enjoying the social interaction with a wonderful group of fellow cyclists.

Amongst our cycling friends we had been the hold-outs on moving to bikes powered by battery electrons rather than leg muscles.

After all, a major reason for our cycling is exercise – why go for a ride where there is no energy expended? No muscles pumped? No cardiovascular huffing and puffing?

Another practical factor that has deterred us from moving to the world of electron-powered cycling is the weight of most of our friends’ e-Bikes – around 24kgs!

Our Campervan has a bike rack fitted to the back doors – but the rack has a 35kg weight limit, which is not enough capacity for 2 x 24 kg e-Bikes. We also need to consider our van’s overall GVM, which is getting close to maxing out when fully loaded (3550kg).

After much consideration, we decided on a compromise e-option – fitting our carbon-frame road bikes with a hub motor and battery, so that they could still be ridden as ‘regular’ bikes most of the time, but with an option to push a button for a little battery-boost on that long climb, when all those riding with us (on their e-Bikes) take off into the distance.

Incorporating a battery and hub motor on our regular bikes provides an e-Boost to our pedaling when required, without a dramatic increase in weight.

We consider our Swytch bikes to be ‘pedal assist’ bikes, rather than full e-bikes. This type of bike has become known as a ‘hybrid’ bike – the best of both worlds!

Taking the e-Plunge

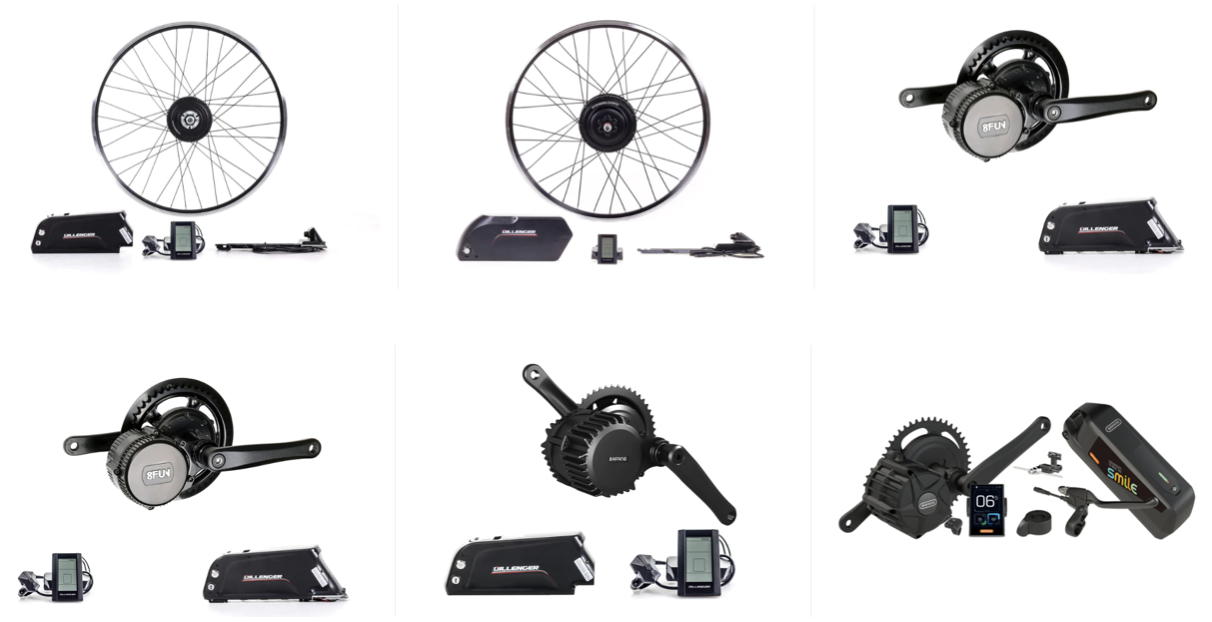

There is no shortage of e-Bike conversion options – it doesn’t take too much Googling to discover the wide range of kit options that are out there…

You have a choice between a central crank motor, or a wheel hub motor. Some are outrageously powerful, others more modest. (Check your local jurisdiction’s legal limits on motor size.) Cost is generally around $800 – $1500 (AUD) for the full kit, plus the time, tools and know-how to install all the bits and pieces.

After weighing up all the options, we chose a Swytch conversion kit from the UK. The Swytch kit….

-

- is a neat all-in-one kit;

- is powered by an easy-to-fit front wheel hub motor (250W);

- has a relatively small battery footprint (that doesn’t consume frame/tube space);

- adds only 3.5kgs to the weight of the bike (with MAX battery);

- has received plenty of positive performance reviews.

If you sign up to the Swytch waitlist, and don’t mind waiting a few months for delivery, you will receive a significant discount off ‘full price’. (Update – our more recent experience has been weeks rather than months.)

We purchased our kits (initially two, but now four including our MTBs) with optional add-ons to the base kit…

-

- MAX battery

- OLED display (experience has proven this to be essential)

- Matte black wheel

- Thumb throttle (MTBs only)

All of which push up the price from the original base level to around $1500 AUD, including delivery. Another factor affecting the cost (here in Australia) is the daily currency exchange rate.

We transferred the tyres, tubes and disc-brake rotors from the front wheels on our existing bikes to the new Swytch wheels on our road bikes, so no additional costs for these items.

-

-

- Other DIY e-Bike kit options: Dillenger | Boost Bike | SmartBikeWheel

- See also: Cap Rouge | TopBikeKit | TDR

- Off-the-shelf e-Bike (with similar specs): Merida eSpeeder

- arsTechnica Swytch review

-

If you are interested in going down the DIY e-conversion path, we have put together some notes about installing our Swytch kits. They have been excellent!

In fact we think they are so good, we have now added Swytch kits to our mountain bikes.

Installation details specific to both our road bikes and mountain bikes are provided below….

|

|

| Swytch Road Bike Installation (and review) |

Swytch MTB Installation (and review) |

Our experience with Swytch support….

We too had a frustrating experience when installing our first Swytch kit back in early 2023. An email to the support team that needed a quick response (fitting the Swytch 10mm axle in our 9mm drop slots) took nearly two weeks to receive a reply. We also experienced some long waits when asking questions before we ordered. But we did eventually receive replies to all our emails to Swytch support. Fast forward to 2025, and the Swytch support team – at least from our antipodean perspective – has been excellent. We now have four bikes powered by Swytch kits – two road bikes and two mountain bikes, along with another six bikes we have fitted out for friends. Over these ten installations, we have experienced a couple of issues that have required support from Swytch – a clicking motor, a faulty battery and a faulty battery mount – and in all three instances we have received a quick response (24-48 hours), and an excellent repair / replace outcome. We can’t expect too much more than that, especially from a support team based on the other side of the planet, operating in a different time zone. From here in Australia we can only offer positive feedback following our recent experiences with the Swytch support team.

|

We probably need to get this out of the way right at the start – an e-Bike conversion is really only viable if you already have a reasonable quality bike languishing in the shed. And you don’t mind undertaking the DIY part of the project.

We probably need to get this out of the way right at the start – an e-Bike conversion is really only viable if you already have a reasonable quality bike languishing in the shed. And you don’t mind undertaking the DIY part of the project.

Various Swytch user forums and online e-Bike discussion groups often dish up negative feedback from Swytch customers who have had a less-than-stellar experience with Swytch support when their kit components have failed, been delivered late, or not operated as expected.

Various Swytch user forums and online e-Bike discussion groups often dish up negative feedback from Swytch customers who have had a less-than-stellar experience with Swytch support when their kit components have failed, been delivered late, or not operated as expected. Well done Swytch!

Well done Swytch!